Steam Power Plant Components- Description with Illustration

An electricity generating station which can produce electricity from a mechanical turbine rotates by steam force applied to it.

Important Site Selection for Installation Steam Power Plant

The site selection of a steam power plant depends upon various factors. Let's discuss these factors one by one-

- Cost of the land: The cost of land which is selected for the installation should be minimum or economical.

- Population density of the land: The distance of the steam power plant from the public area should be at the appropriate distance. So that in case of any failure or hazard happening in the plant, the population of the area near the power plant should not be affected.

- Availability of water sources: There should be plenty of water sources in the selected area. The power plant requires a large amount of water for the generation of steam.

- Availability of fuel: The availability of required fuel(coal) should be there because without fuel the will not work.

- Type of land: The land which is selected for the power plant installation should be plain enough and it is suitable for the strong foundation for the various machinery of the plant.

- Scope for the future demand: The size of the land should be such that it is capable handling of future power demand.

- Availability of ash handling facility: Proper ash handling facility should be available near the power plant to minimize the adverse effect of the ash produced in the steam power plant.

- Availability of transportation facility: The transportation facility is a must in the installation of the power plant because any material cannot be transported to the power plant from its required location in lack of transport. There should be easy availability of prop transportation facilities at the selected site.

General Layout Diagram of a Steam Power Plant

What actually Happens inside

Components of Steam Power Plant

- Boiler

- Steam turbine

- Generator

- Condenser

- Cooling towers

- Circulating water pump

- Boiler Feed pump

- Economizer

- Superheater

- Re Heater

- Air Heater

- Boiler Chimney

- Water treatment plant

- Coal Mill

- Control room

Description of Components

Boiler:

It converts the water into high-pressure steam. It contains the furnace inside or outside the boiler shell. The combustion of coal takes place in the furnace. The boiler has the function to convert water into steam.The process of change of water to vapor is done by heating the water in the pipes with heat from burning fuel. Combustion processes are carried out continuously in the combustion chamber with fuel and airflow from the outside.

The resulting steam is superheated steam which has high temperature and high pressure.

Steam production quantities dependent on the surface area of heat transfer, flow rate, and the heat of combustion are given.

Boiler construction consists of water-filled pipes called a water tube boiler.

Turbine:

It is the mechanical device that converts the kinetic energy of the steam to mechanical energy. Steam turbines work to change the heat energy contained in the steam into rotary motion.Steam with high pressure and temperature was directed to push turbine blades mounted on the shaft. So the shaft rotates.

Due to performing work on the turbine, the pressure, and temperature of steam coming into the turbine down to saturated vapor.

This steam then flows to the condenser, while the rotary power is used to turn a generator. Today almost all steam turbine is a type of condensing turbine.

Generator:

It is coupled with the turbine rotor and converts the mechanical energy of the turbine to electrical energy. The main purpose of the activities at a plant is electricity.The electrical energy is generated from the generator. The function generator converts mechanical energy into electrical energy in the form of a round with the principle of magnetic induction.

The generator consists of a rotor. The stator consists of the casing which contains coils and a rotor magnetic field station consists of a core containing a coil.

Condenser:

It condensates the steam that leaves out the turbine. The condenser converts the low-pressure steam to water. The cooling tower attaches to it.Condensers are devices to convert steam into water. the changes are done by the steam flow into a room containing tubes. Steam flows outside tubes, while the cooling water flows inside the tubes. This is called the surface condenser. Usually for coolant use seawater.

The heat transfer rate depends on the flow of cooling water, sanitation tubes, and the temperature difference between the steam and cooling water.

The process of change into water vapor occurs at saturated pressure and temperature, in this case, the condenser is under a vacuum. Because the cooling water temperature is equal to the outside temperature, the maximum temperature condensate water near the outside air temperature.

If the rate of heat transfer is interrupted it will affect the pressure and temperature.

Cooling tower:

Feed Water Pump:

Economizer:

Coal Storage:

Ash Storage:

Dust Collector:

Advantages and Disadvantages of Steam Power Plant

The advantages and disadvantages of steam power plants are as follows:

Advantages:

- As compared with the power generating plant, it has a low initial cost and hence economical.

- Compared with the hydropower plant requires less land area.

- For financial advantage, people use coal-like fuel and the cost of coal is cheaper than petrol and diesel fuel. So the power generation cost is economical.

- This power plant has an easy maintenance cost.

- The steam power plant can be installed in any area where water sources and transportation facilities are easily available.

Disadvantages:

- The running cost of the steam power plant is comparatively high because of fuel, maintenance, etc.

- It talks about the overall efficiency of the steam power plant that is about 35% to 41% which is low.

- Due to the release of burnt gases of coal or fuel, contributes to global warming to a larger extent.

- When the heated water threw into rivers, ponds, oceans, etc, then it puts an adverse effect on the living organism of water and disturbs the ecology.

Some Key Components of Illustration

1. Boiler

- A boiler is a closed vessel in which water under pressure that converted into steam.

- It is one of the major components of a thermal power plant which always designs to absorb the maximum amount of heat released in the process of combustion

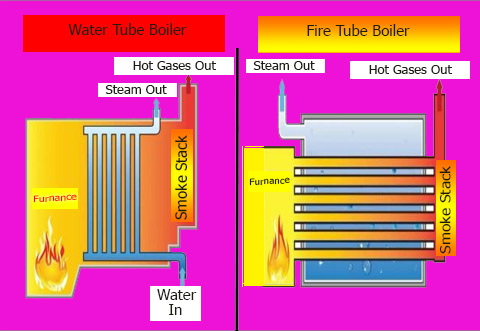

- Fire-tube boiler

- Water-tube boiler

Important parts of the boiler are-

1. Steam Drum

2. Superheater & Re-heater

3. Attemperator

4. Air preheater

5. Drain % Vent

6. Economizer

2. Feed Water Heater

- Advantages of heating water before feeding back to the boiler:-

- Feedwater heating improves overall plant efficiency.

- The dissolved oxygen and carbon dioxide which would otherwise cause boiler corrosion are removed in the feedwater heater

- The thermal quantity of steam produced by the boiler is increased.

- Some other impurities carried by the steam and condensate, due to corrosion of the boiler and condenser are precipitated outside the boiler.

Vapor Power Cycle

Steam Power Plant

2. Rankine Cycle: The Ideal Cycle for vapor Power Cycles

- Steam Engine and Steam Turbines which as working medium follow the Rankine cycle uses steam.

- Ideal Rankine Cycle does not involve any internal Irreversibillties and consists of the following 4 processes

3-4: Isentropic Expansion in a turbine

3. SUPERHEATER (LITERATURE)

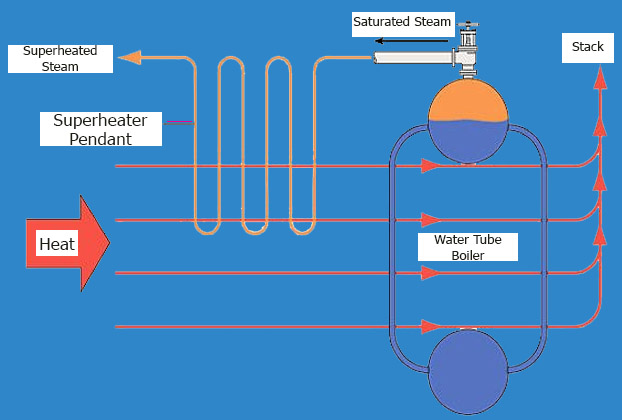

A superheater is a device that uses to convert saturated or wet steam into superheated steam used in steam engines or in processes. Such as steam reforming.It is an integral part of the boiler. And it is placed in the path of hot flue gases from the furnace.

In superheating the steam before entering into the turbine use the heat recovered from the flue gases (i.e prime mover). Its main purpose is to increase the temperature of saturated steam without raising its pressure.

Most modern boilers are having a superheater and reheater arrangement.

The superheater is a component of a steam-generating unit in which steam. After it has left the boiler drum. It heated above its saturation temperature. The location influences the amount of superheat added to the steam.

The arrangement, and amount of superheater surface installed, as well as the rating of the boiler.

The superheater may consist of no more stages of tube banks arranged to effectively transfer heat from the products of combustion. Superheaters are classified as convection. Radiant or a combination of these.

4. Economizer

- Flue gases coming out of the boiler carry a lot of heat.

- An economizer extracts part of this heat from flue gases and uses it for heating feed water.

- This use of economizer results in saving coal consumption and higher boiler efficiency.

.png)

.png)